Verde Technologies / Company Spotlight

CEO Skylar Bagdon describes Verde's lightweight perovskite solar panels and path to commercialization

Verde Technologies Inc. is developing an innovative alternative to traditional silicon solar panels.

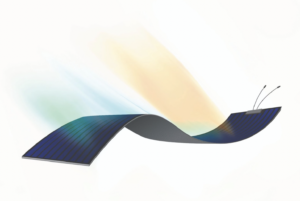

Headquartered in Burlington, this renewable energy company manufactures thin-film solar panels using the mineral perovskite. The product adheres to virtually any surface, making solar energy a viable option for all sunlit households.

“We started hearing that 40 percent of rooftops cannot handle the weight of conventional solar modules,” said Randall Headrick, Verde’s research lead, in a 2022 interview with UVM. “It turns out that thin-film solar can beat conventional solar by something like a factor of 8 on weight.”

Verde’s journey began in 2018 when Headrick and his post-doc, Richards (Chad) Miller, joined forces. University of Vermont professor Headrick had been researching thin-film deposition methods for decades, and found a partner in Miller, who had just finished his Ph.D. in Physics at the University of Utah.

Over the past five years, Headrick and Miller have developed a panel with a flexible form factor and a peel-and-stick application, weighing 87% less than conventional silicon panels. In August 2021, the company was accepted into the University of Vermont’s Academic Research Commercialization (ARC) program, accelerating the commercialization process.

“A lot of folks are either not focusing on stability or low-cost manufacturing,” said Skylar Bagdon, the founding director of ARC, who was appointed as Verde’s CEO last fall. “So we differentiate [from counterparts in the perovskite space] with a flexible form factor and then we focus on creating low-cost and stable technologies.”

Last August, the team won the Department of Energy’s Perovskite Prize, which included a $200,000 cash award. Shortly after, Verde secured second place and the People’s Choice award at the Cleantech Open, featuring over 90 companies. These achievements earned Verde recognition in the solar energy world.

By then, Verde was seeking to complete its first fundraising round.

“Our success [at the Cleantech Open] was a big confidence moment and a bunch of VC funds started reaching out,” said Bagdon. “But I’ve known VCET since 2017 and I knew that we needed people in our corner we could trust. So right after the competition, I told Sam and Dave I wanted them to be the lead investor in our first fundraise. We closed the deal on December 30 of 2022.”

Verde supplemented the round with other VC funds and value-add angel investors, allowing expansion of the team and advancement of the technology. In March, Verde hired Miami-based research scientist Pramod Baral, who joined Chad Miller, the President/CTO, and Bagdon as full-time employees. Head of Partnernships Nicole Eaton and Headrick work part-time.

The team also recently hired Dr. John Tuttle, who has previous experience scaling thin-film solar companies, to help with strategy.

In April, Verde achieved another significant milestone by being selected as a commercial partner for the DOE Solar Energy Technologies Office (SETO) $11.25 million cost-shared award. In partnership with Massachusetts-based CubicPV, Verde will collaborate with the Massachusetts Institue of Technology (MIT), the University of California at San Diego, and Princeton University to establish a pervoskite solar tech center, expediting the advancement of perovskite solar cell production.

“We’re really one of the first solar companies in the world to use perovskites and get as far as we are now,” said Eaton. “And we’ve developed the business this far in less than two years.”

One of Verde’s primary challenges will be convincing customers to adopt its technology.

“Energy customers are very risk averse,” said Bagdon. “People want a technology that’s proven, they want to know it’s gonna last for decades, and they want to know that it’s low cost. The solar industry is mature and global, so we’re competing against large-scale manufacturers in China.”

Hence, Verde’s initial focus is on roofs unsuitable for traditional solar panels due to structural integrity of orientation issues. This approach will allow Verde to prove the technology and value proposition before addressing a wider market.

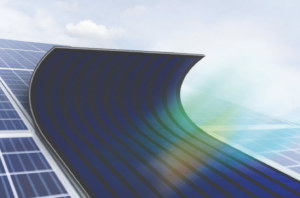

One exciting application is the revitalization of end-of-life solar fields, which are traditionally expensive to renovate.

“It’s expensive to pay a crew to rip old panels out, dispose of them, and then install an entirely new system,” said Bagdon. “So what we’re looking to do is allow all the existing infrastructure to stay in place, and essentially put a thin film of flexible solar panels right on top.”

Looking ahead, Headrick anticipates completing Verde’s outdoor testing facility at UVM by fall 2024, which will provide insights into panel effectiveness under sunlight. Rooftop testing is scheduled to follow the following year. The company continues to use UVM’s lab space, along with VCET and Hula’s coworking space.

Verde also recently achieved a significant milestone by printing 200 feet of their perovskite ink on a full-scale manufacturing line, advancing towards their commercial product.

Verde’s next step will be to raise a $7 million seed round.

“We are just getting started,” Eaton said. “Next year is going to be absolutely insane.”

To learn more about Verde, explore their redesigned website. For additional information, you can contact Nicole Eaton at nicole@verdetechnologies.com.